🤖 Kyrie Irving Was Shocked

Good Morning, Roboticists!

Kyrie Irving’s courtside surprise ended up being the least wild robotics moment of the week.

HUMANOIDS

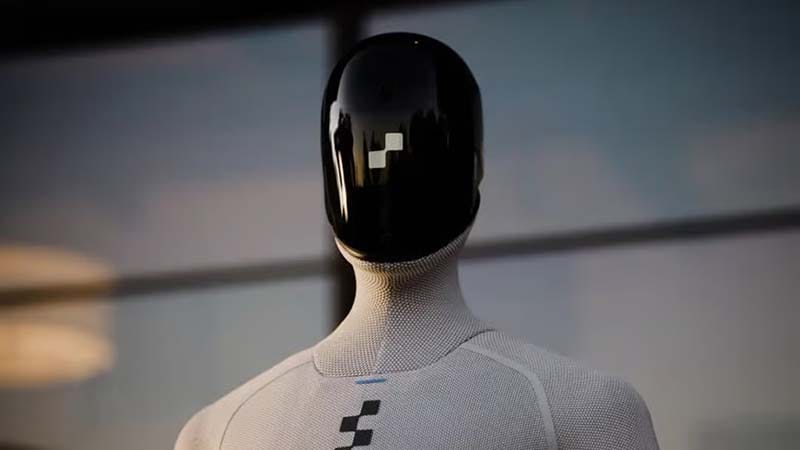

An Expensive Robot That Can’t Take a Push

A Mavericks video shows Kyrie Irving facing off with a flashy humanoid robot that confidently throws a roundhouse kick, then immediately forgets how gravity works. One shove and the machine collapses, motionless. Irving apologizes and helps it up, but the damage is done. The clip goes viral not because of human dominance, but because a supposedly advanced robot folds like stage furniture the moment real contact happens.

What this actually exposes is a brutal hardware truth. This robot is not rugged, not compliant, and not demo ready. It behaves less like a worker and more like a porcelain liability. In factories, warehouses, or public spaces, falling is not an edge case. It is the default failure mode. A robot that cannot absorb a shove is not a platform. It is an insured asset waiting to be written off.

If a light push bricks the system, it is not embodiment. It is cosplay with actuators. Right now this robot looks less like labor and more like an expensive insurance claim waiting to happen.

HUMANOIDS

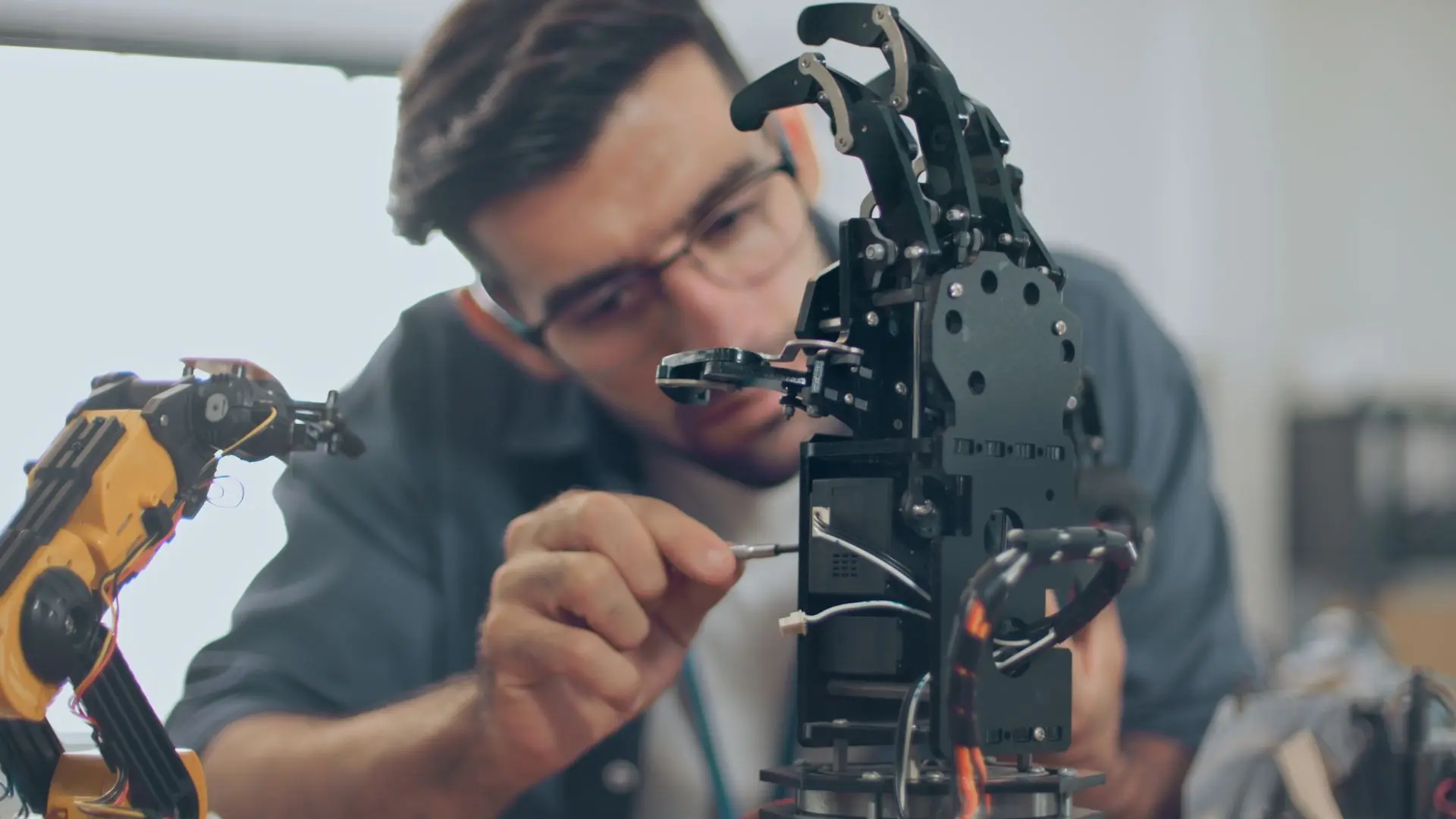

A Startup Building Terminators

Foundation, a San Francisco robotics startup, has openly declared plans to deploy up to 50,000 humanoid robots by 2027 for military and high-risk industrial zones. Its Phantom MK-1 is explicitly designed for combat adjacent roles like reconnaissance, bomb disposal, and frontline ground operations. The CEO describes it as the “first body in,” a deliberate reframing where robots, not soldiers, absorb initial battlefield risk. No safety theater. No lifestyle robotics narrative.

Phantom MK-1 is built like a human because war and heavy industry are built for humans. Cameras over fragile sensor stacks, high torque cycloid actuators, and a form factor meant to walk through doors, climb stairs, and take hits. Leasing at roughly $100,000 per year signals continuous deployment and expected attrition. This is not automation for efficiency. It is robotics as a consumable operational asset.

Once humanoids are framed as expendable frontline units, the threshold for deploying force quietly drops. When the first casualty is hardware, escalation becomes an operational choice, not a political one. That shift matters far beyond robotics.

NEW TECH

Wind-Surfing Robot Rethinks Rough Terrain

EPFL researchers have built HERMES, a hybrid robot that rolls like a tumbleweed and flies like a drone. Published in Nature Communications, it uses a porous spherical shell inspired by real tumbleweeds, converting wind drag into forward motion while carrying sensors and small payloads. When stuck, a built-in quadcopter gives it a short lift or directional nudge, cutting energy use by nearly half compared to conventional mobile robots.

HERMES isn’t a Mars rover with wheels; it’s a wind-powered explorer that coasts until the physics stop cooperating. The system’s strength lies in its passive-to-active energy logic, making it ideal for vast, hazardous terrains where batteries die faster than missions finish. Think planetary mapping, post-disaster scouting, or drifting over minefields, places where you’d rather send a rolling sphere than a six-figure rover with legs.

When you build a robot that literally rolls with the wind, you’re no longer automating movement; you’re negotiating with nature’s physics engine for free propulsion.

QUICK HITS

- Inaho’s harvesting robot is being trialed in Dutch greenhouse snack tomato farms to work alongside humans in commercial tomato harvesting.

- Generalist AI’s technical addendum argues that data quality and composition, not sheer scale, are central to robotic pretraining.

- Neura Robotics has shifted 4NE-1 humanoid R&D to Zurich to leverage the ETH Zurich ecosystem for embodied AI.

- Advanced Intralogistics and AlphaOne Robotics are teaming up to automate trailer unloading with AI-powered robots across North America.

- Hyundai Steel is accelerating smart manufacturing by deploying robots across tagging, inspection, and shipping processes in its steel plants.

TOGETHER WITH US

AI Secret Media Group is the world’s #1 AI & Tech Newsletter Group, reaching over 2 million leaders across the global innovation ecosystem, from OpenAI, Anthropic, Google, and Microsoft to top AI labs, VCs, and fast-growing startups.

We operate the industry’s most influential portfolio of newsletters, each shaping a different frontier of the AI & Tech revolution:

Be Smarter in 5 Minutes

- AI: AI Secret

- Tech & Business: Bay Area Letters

- Marketing: Marketing Secret

Discover the Future Products

- AI Launchpad: Oncely

- Robotics: Robotics Herald

- Hardwares: The Hardwire

We've helped promote over 500 Tech Brands. Will yours be the next?

Email our co-founder Mark directly at mark@aisecret.us if the button fails.